Comprehensive Guide to PLC Control Cabinets

Jan 13, 2025

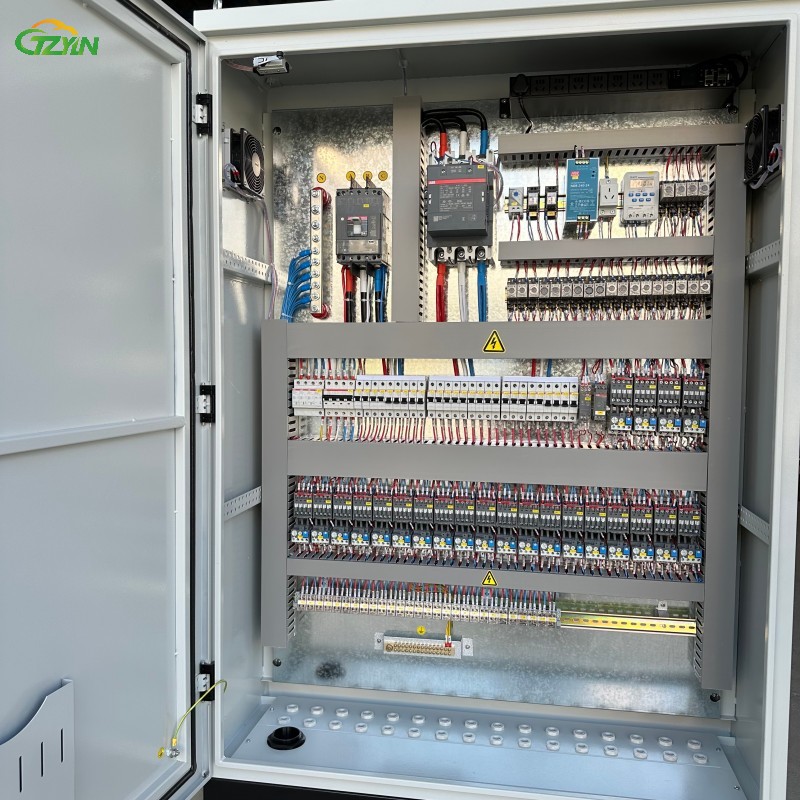

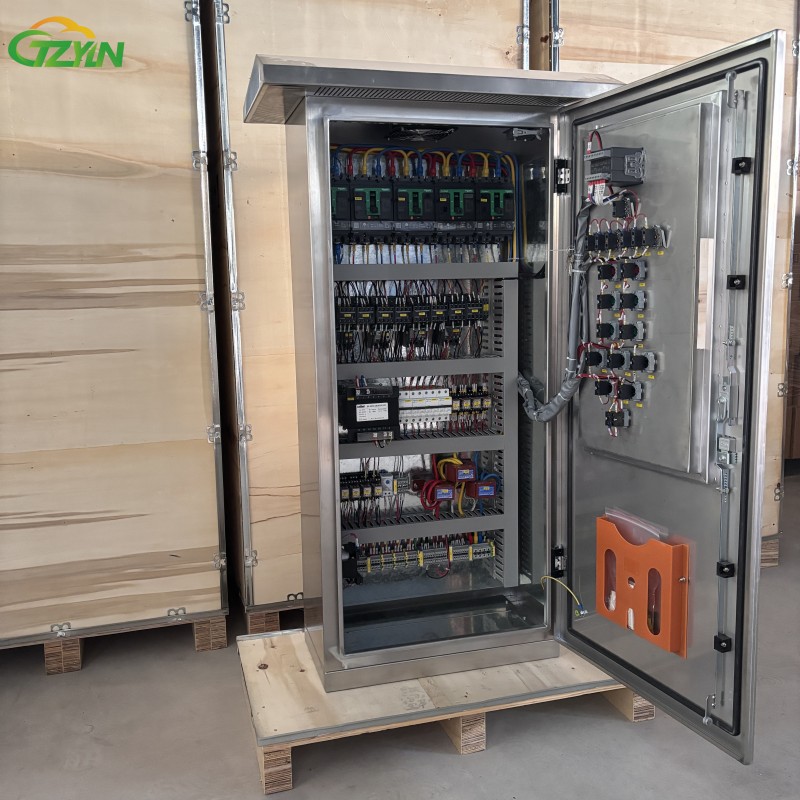

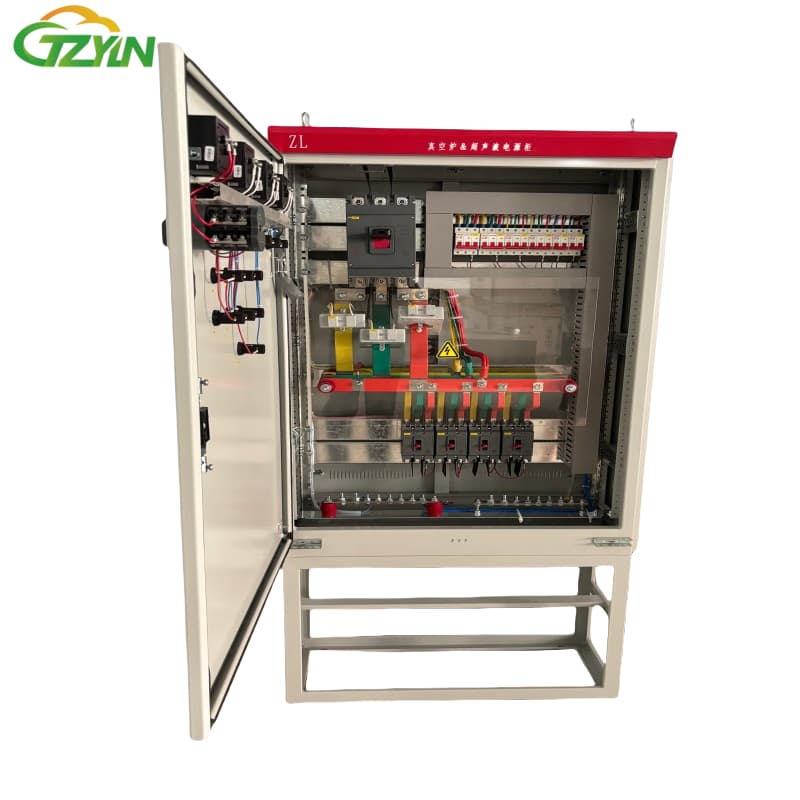

PLC control cabinet, also known as programmable logic controller control cabinet, is an indispensable part of industrial automation. It receives signals from various sensors and input devices, uses its built-in programmable logic controller (PLC) for signal processing and judgment, and controls output devices to achieve automated control of machinery or process.

Design principles of PLC control cabinet:

1. Security

Ensure that all electrical components comply with relevant safety standards.

Set up emergency stop buttons and protective circuits to prevent misoperation and accidents.

2. Reliability

Choose high-quality electrical components and materials.

Design redundant systems to improve the overall reliability of the system.

3. Standardization

Follow international and domestic electrical design standards.

Use standardized components and interfaces for easy maintenance and upgrades.

4. Efficiency

Optimize electrical layout to reduce line length and complexity.

Choose appropriate PLC and expansion modules to improve processing speed and response time.

What are the application areas of PLC control cabinets?

Manufacturing industry: In industries such as automobile manufacturing, machinery manufacturing, and electronics manufacturing, PLC control cabinets are used to control and monitor various equipment and processes, including robots, assembly lines, conveyor belts, furnaces, etc.

Industrial Automation: As the core component of industrial automation, PLC control cabinets are used to control and monitor various equipment and systems in factories, such as motors, sensors, valves, hydraulic systems, etc. Through programming, automation and centralized control are achieved, improving production efficiency and quality.

Water treatment and sewage treatment: PLC control cabinets are used to monitor and control the water treatment process, including the control of equipment such as pumps, filters, valves, as well as the monitoring of parameters such as water quality, flow rate, and pressure, to ensure the stable operation and performance of the water treatment process.

Energy and power industry: In the energy and power industry, PLC control box are used to monitor and control power generation, transmission, and distribution systems, including control of generators, transformers, switchgear, etc., and monitor parameters such as voltage, current, power factor, etc., to improve the efficiency and reliability of energy and power systems.

Chemical and pharmaceutical industries: PLC control panel are used to control and monitor various chemical reactions and production processes, including the control of equipment such as mixers, reactors, and reactors, as well as the monitoring of parameters such as temperature, pressure, and concentration, to ensure the safety and stability of chemical and pharmaceutical processes.

Food and beverage industry: In the food and beverage industry, PLC control cabinets are widely used to control and monitor production processes, such as controlling equipment such as mixers, heaters, filling machines, as well as monitoring parameters such as temperature, pressure, pH, etc., to ensure hygiene and quality in the food and beverage production process.

Environmental Protection: PLC control cabinets are used to control and monitor environmental facilities and treatment systems, such as sewage treatment plants, garbage incineration plants, waste gas treatment equipment, etc., and monitor parameters such as pollutant concentration, temperature, humidity, etc., to ensure the operation and treatment effectiveness of environmental protection facilities.

Transportation: PLC control cabinets can be used for control systems in rail transit such as subways and high-speed trains, as well as for automated control of traffic signal lights and monitoring systems, ensuring safe and smooth traffic.

Other fields: PLC control cabinets are also used in multiple heavy and light industries such as steel, petroleum, chemical, power, building materials, papermaking, environmental wastewater treatment, as well as cultural and entertainment industries. In addition, it can also be used for various occasions such as data acquisition, signal monitoring, and network communication.

Daily maintenance and upkeep of PLC control cabinet

1. Regular inspection

Regularly check the status of electrical components and replace damaged or aged parts in a timely manner.

Check if the wiring is loose and ensure a reliable connection.

2. Cleaning and maintenance

Regularly clean the dust and debris inside and outside the control cabinet to prevent dust accumulation and poor heat dissipation.

Check if the radiator is working properly and clean or replace it if necessary.

3. Software maintenance

Regularly backup PLC programs and data to prevent data loss.

Adjust and optimize control programs based on actual operating conditions to improve system performance.

4. Safety inspection

Regularly check whether the safety circuit and emergency stop device are working properly.

Ensure that all safety measures are in place to prevent the occurrence of safety accidents.