Guozhi Cloud Soft Start Control Cabinet: Intelligent Guardian of Industrial Power

Dec 25, 2024

In today's industrial field, stable start-up and operation of motor equipment are crucial for the smooth operation of the entire production process. As a key control device, the soft start control cabinet is playing an indispensable role. Guozhi Cloud stands out in the field of soft start control cabinets with its outstanding technological strength and innovative spirit, providing reliable solutions for many industrial enterprises.

1. Core advantages of soft start technology

The core of the soft start control cabinet lies in its advanced soft start technology. Compared with the traditional direct starting method, soft start can effectively reduce the impact current when the motor starts, avoid the instantaneous large current impact on the power grid, thereby reducing the power grid voltage fluctuation caused by excessive starting current and ensuring the entire The stability of the power supply system. This is of great significance for some precision equipment production workshops with higher voltage stability requirements or areas with more sensitive power supply.

At the same time, the soft start process can also significantly reduce the mechanical stress experienced by motors and mechanical equipment at the moment of startup. By slowly increasing the voltage and speed of the motor, the motor can smoothly accelerate to the rated speed, avoiding sudden torque impacts, extending the service life of the motor and related mechanical equipment, reducing equipment maintenance costs and downtime, and improving production. efficiency.

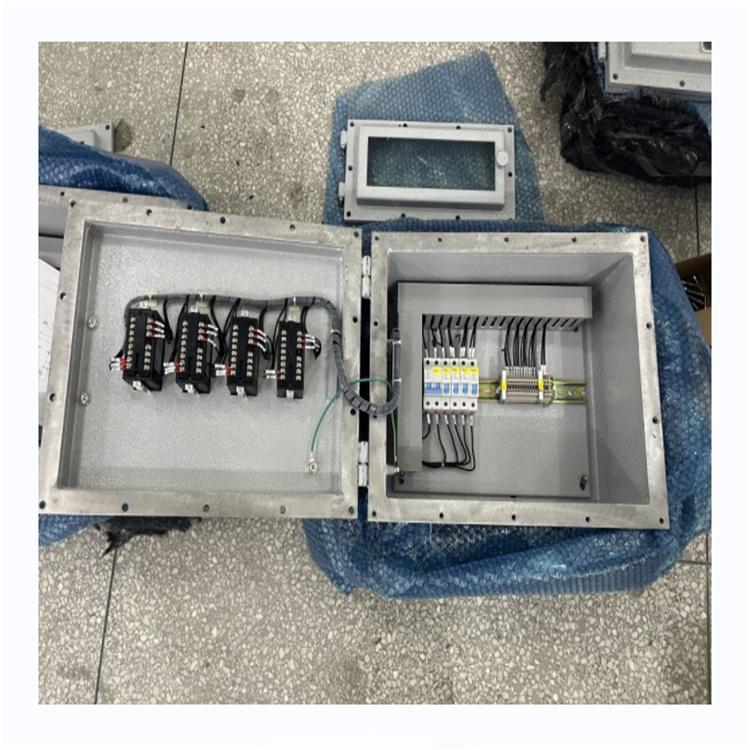

2. Features of Guozhiyun soft start control cabinet

Intelligent control: Guozhiyun's soft-start control cabinet is equipped with an intelligent control system, which can automatically adjust the starting parameters according to the load characteristics and actual operating conditions of the motor to achieve precise soft-start control. Operators can easily set and monitor the starting curve, current limit, time parameters, etc. through the human-machine interface. The operation is simple and intuitive, which greatly improves the operability and adaptability of the equipment.

Multiple start modes: In order to meet the needs of different industrial scenarios, our soft start control cabinet provides a variety of start modes, such as voltage ramp start, current limit start, torque control start, etc. Users can flexibly select the most appropriate starting mode based on the motor type, load conditions and process requirements to ensure that the motor can start smoothly and reliably under various working conditions.

Complete protection functions: Built-in comprehensive protection functions, real-time monitoring and protection of motor overload, short circuit, under-voltage, over-voltage and other faults. Once an abnormal situation occurs, the control cabinet can quickly cut off the power supply to protect the motor and other equipment from damage. At the same time, an alarm signal is issued to remind the operator to deal with the fault in a timely manner and minimize the downtime loss.

Remote monitoring and communication: In the era of Industry 4.0, Guozhiyun soft start control cabinet has remote monitoring and communication functions. Through network connection, users can remotely monitor the operating status, parameter settings, fault information, etc. of the equipment anytime and anywhere to achieve remote operation and management. This not only facilitates the centralized management and maintenance of production equipment by enterprises, but also enables timely response to equipment failures, improving the continuity and reliability of production.

3. Wide range of applications

Guozhiyun soft start control cabinet has been widely used in many industrial fields due to its excellent performance and reliable quality. In the mining industry, it is used to control the start-up of large motor equipment such as crushers, ball mills, and ventilators, ensuring the stable operation of mining production equipment and improving production efficiency and safety; in the field of iron and steel metallurgy, it is used for steel rolling mills and blast furnace blowers. , cranes and other equipment provide soft-start protection, reducing equipment failure rates and maintenance costs, ensuring the continuity of steel production; in sewage treatment plants, soft-start control cabinets are used in sewage pumps, aerators and other equipment to effectively solve It eliminates the problem of impact on the power grid when the motor starts, increases the service life of the equipment, and ensures the stable operation of the sewage treatment process.

What is the control of a soft starter?

A soft starter continuously controls the motor's voltage supply during the start-up phase. This way, the motor is adjusted to the machine's load behavior. Mechanical operating equipment is accelerated smoothly. This lengthens service life, improves operating behavior, and smooths work flows.

How does a soft start controller work?

Electric soft starters operate by sending voltage through a series of connected semiconductors. During a soft start, these components can be configured to gradually allow an increasing amount of current to pass through.

What is soft starter in motor control?

A soft starter is a solid-state device that protects AC electric motors from damage caused by sudden influxes of power by limiting the large initial inrush of current associated with motor startup. They provide a gentle ramp up to full speed and are used only at startup (and stop, if equipped

What is the difference between a VFD and a soft start?

In closing, a VFD and a Soft Starter can do similar functions when it comes to ramp up or down a motor. The main difference between the two is that a VFD can vary the speed of a motor while a soft starter only controls the starting and stopping of that motor.