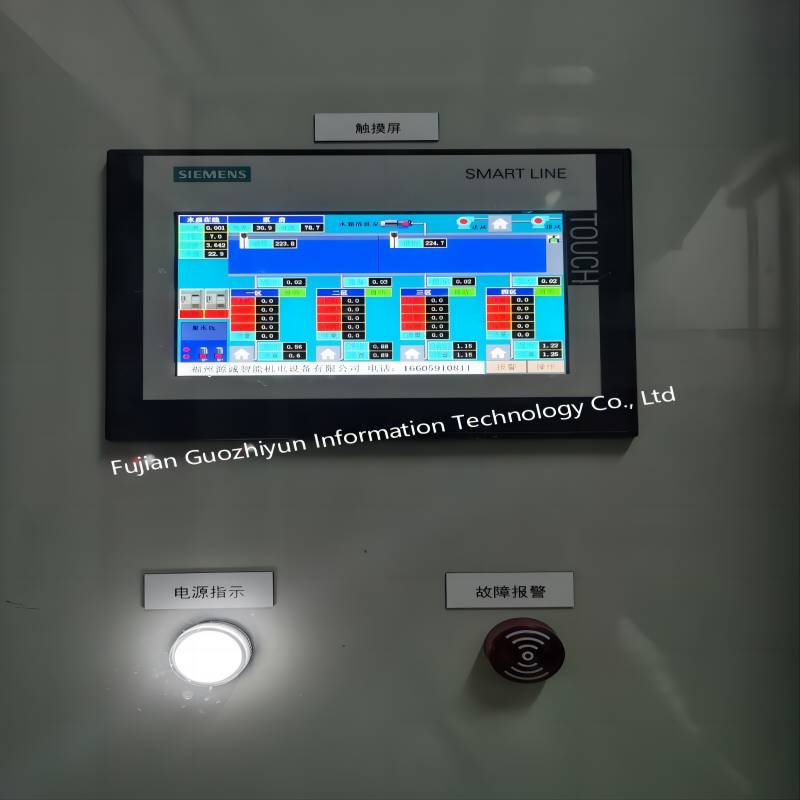

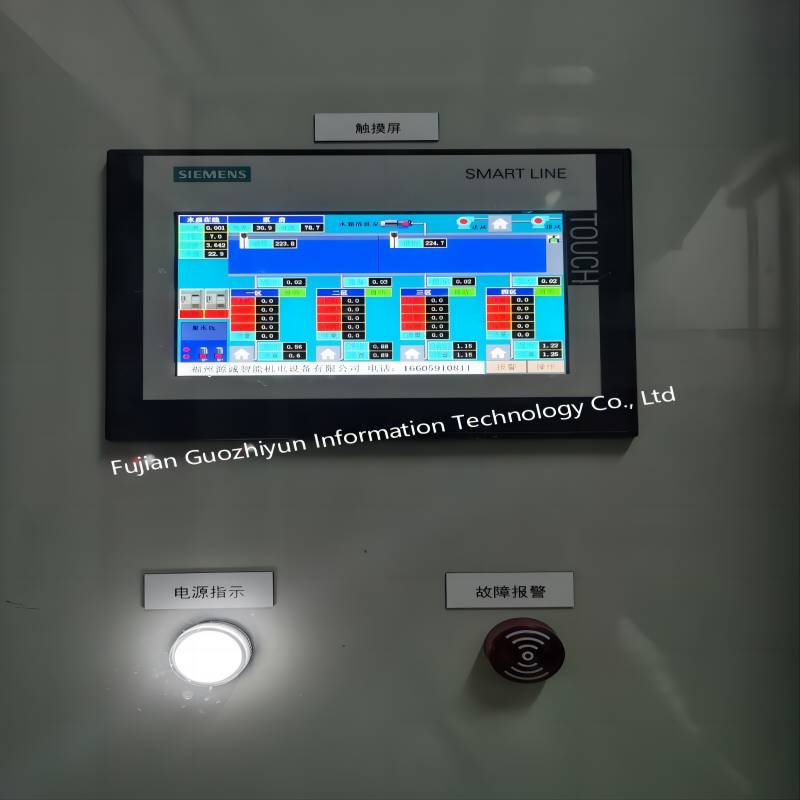

PLC control cabinet refers to an electrical control cabinet that integrates a programmable logic controller (PLC), used to achieve automatic control of equipment such as motors and switches.

PLC control cabinet is the core component of modern industrial automation. It provides efficient, stable, and economical production control solutions for enterprises through real-time monitoring and control, sensitivity design, reliability assurance, and data acquisition and analysis functions.

Advantages And Characteristics:

- Programmable: The PLC in the PLC control cabinet can be programmed as needed to flexibly adapt to different control tasks.

- Communication: PLC control panel typically have communication interfaces that allow for data exchange and communication with other devices, enabling remote monitoring and control.

- Overload protection: The PLC control cabinet has overload, short circuit, and phase loss protection functions to ensure the safe and stable operation of the system.

- High protection level: PLC control cabinets usually have a high protection level, such as IP65, which can prevent dust and water, and are suitable for harsh environments.

- Strong compatibility: The electrical components inside the PLC control cabinet can be selected from international major brands such as Siemens, Schneider, etc., to ensure the compatibility and stability of the system.

- Customized design: Tailored PLC control cabinets according to user needs to meet the requirements of specific application scenarios

Application area:

- Manufacturing industry: In industries such as automobile manufacturing, machinery manufacturing, and electronics manufacturing, PLC control cabinets are used to control and monitor various equipment and processes, including robots, assembly lines, conveyor belts, etc.

- Industrial Automation: PLC control cabinets are used in the field of industrial automation to control and monitor various equipment and systems in factories, such as motors, sensors, valves, etc. Through programming, automation and centralized control are achieved to improve production efficiency and quality.

- Water treatment: In the field of water treatment and sewage treatment, PLC control cabinets are used to monitor and control the water treatment process, ensuring stable operation of parameters such as water quality, flow rate, and pressure.

- Energy and Power: In the energy and power industry, PLC control cabinets are used to monitor and control power generation, transmission, and distribution systems, improving the efficiency and reliability of energy and power systems.

- Chemical pharmaceuticals: In the chemical and pharmaceutical industries, PLC control cabinets are used to control and monitor various chemical reactions and production processes, ensuring the safety and stability of chemical and pharmaceutical processes.

- Environmental Protection: In the field of environmental protection, PLC control cabinets are used to control and monitor environmental facilities and treatment systems, such as sewage treatment plants, garbage incineration plants, etc., to ensure the operation and treatment effectiveness of environmental protection facilities.

- Metallurgical and Chemical Industry: In industries such as metallurgy, chemical engineering, and building materials, PLC control cabinets are used to achieve complex production process control and monitoring.