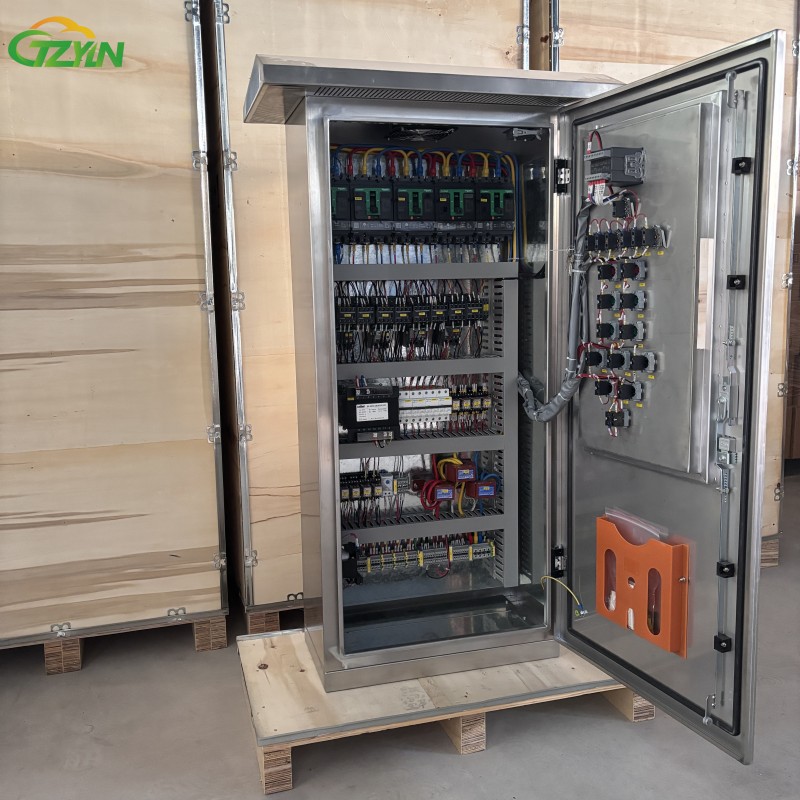

Philippine garbage station control cabinet control box project

Jan 22, 2025

The smart core of Philippine garbage stations leads the new trend of environmental protection

This garbage rake control cabinet is a key hub in the garbage disposal system. It is responsible for accurately controlling the operation of the garbage rake, whether it is the automatic sorting, crushing, compression and incineration processes of garbage, they are all carried out in an orderly manner under its strict control. Through advanced automation technology, the efficiency and intelligence of the entire garbage disposal process have been achieved, greatly improving the processing capacity and efficiency of Philippine garbage stations.

Safety is always the primary consideration. Therefore, Guozhiyun has carefully integrated multiple security protection mechanisms into its design. According to the unique requirements of the garbage truck transportation process, an emergency stop button is equipped. In case of an unexpected situation, the operator only needs to lightly press it to immediately stop the equipment, effectively avoiding accidents. At the same time, the installed anti-collision sensors are like sharp antennae that can monitor the surrounding environment in real time. When an object approaches a dangerous distance, the system will quickly react and automatically pause the operation of the equipment, thus building a solid safety line for operators and surrounding equipment.

In terms of environmental protection and energy conservation, Guozhiyun also performs well. The internal use of low-power components and energy-saving control technology not only reduces the energy consumption of the equipment itself, but also meets the environmental protection policy requirements of the Philippine government, helping the local area achieve sustainable development goals. Moreover, the garbage rake control cabinet also has the potential to be combined with the garbage incineration power generation system, which means that while solving the problem of garbage disposal, it can also convert garbage into valuable energy, provide sustainable energy supply for the Philippines, turn waste into treasure, and achieve resource recycling.

Guozhiyun's garbage rake control cabinet box, with its excellent performance, safe and reliable design, and environmentally friendly and energy-saving features, has brought innovative solutions to the waste treatment industry in the Philippines and become an important force in promoting local environmental protection.

What is a control cabinet?

A control cabinet panel is an enclosure that houses electrical and electronic components used to control machinery or processes, typically in manufacturing, automation, and power distribution systems. It contains devices such as programmable logic controllers (PLCs), relays, circuit breakers, and operator interfaces, protected by a durable metal shell to ensure safety and reliability in industrial environments.

In which industries are control cabinets widely used?

Manufacturing industry: used for production line control systems, precise control of various machine tools, automation equipment, etc., to achieve efficient production of products; It can also be used in robot systems to control the actions and operational processes of robots.

Energy industry: In substations and power plants, control cabinets are used for power distribution and control to ensure the stable operation of the power system; It is also used for monitoring and managing new energy equipment such as wind power generation and solar power generation.

Chemical industry: precise control of chemical reaction processes, adjusting parameters such as temperature, pressure, and flow rate to ensure product quality and safety

Power system: used in dry-type distribution systems to control and protect electrical equipment inside buildings, prevent overload, short circuit and other faults, and ensure the stable operation of the power system; Simultaneously, it can achieve power grid operation scheduling and power load management.

Air conditioning system: controls and protects air conditioning equipment, automatically adjusts the operating status of the air conditioning based on factors such as indoor and outdoor temperature.

Rail transit: used in subway, light rail, railway and other systems to monitor and control rail transit equipment in real time, ensuring the safe, timely and economical operation of trains.

Wastewater treatment: Control the operation of wastewater treatment equipment, such as water pumps, valves, mixers, etc., to achieve automation and optimized control of the wastewater treatment process.