Stering Power Quality: The Magic of Active Filter Cabinets

Apr 15, 2025

In the complex web of modern industrial and commercial electrical systems, power quality is a linchpin that holds everything together. But if you've been in the game for a while, you know all too well the headaches caused by power irregularities. Harmonics, in particular, can be a real nightmare. They lurk in the shadows, causing inefficiencies, skyrocketing energy bills, and even premature equipment failure. But fear not, because there's a superhero in the world of electrical engineering - the active filter cabinet.

The Harmonic Menace: What You Need to Know

Harmonics are like the unwanted guests at a party. They're the result of non - linear electrical loads such as variable - speed drives, arc furnaces, and switch - mode power supplies. These loads distort the pure sine - wave of your electrical supply, creating harmonics that can ripple through your entire system. The consequences? Motors may overheat, capacitors can fail prematurely, and sensitive electronic equipment like PLCs and computers can malfunction. It's not just about equipment breakdowns; it's also about lost productivity and increased maintenance costs.

How Active Filter Cabinets Save the Day

Real - Time Harmonic Detection and Elimination

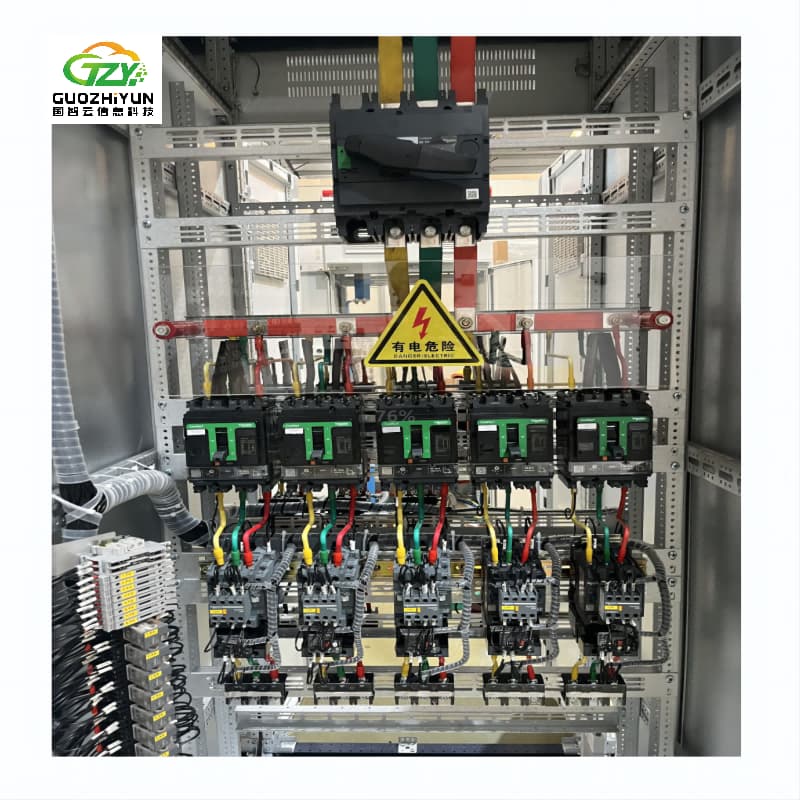

Active filter cabinets are equipped with advanced sensors and intelligent algorithms. These components work in tandem to continuously monitor the electrical current in your system. The moment they detect harmonic frequencies, they swing into action. The cabinet generates counter - currents that are the exact opposite of the detected harmonics. It's like a Jedi using the Force to neutralize the dark side. These counter - currents combine with the harmonics in the system, effectively canceling them out and restoring the power supply to its pure, distortion - free state.

Reactive Power Compensation: A Hidden Gem

Beyond harmonic mitigation, active filter cabinets are pros at reactive power compensation. Many of the electrical loads in industrial and commercial settings, such as motors and transformers, are inductive in nature. They consume reactive power, which can lead to a lower power factor. A low power factor is like having a leaky bucket - your electrical system has to work harder to deliver the same amount of useful power. Active filter cabinets constantly monitor the reactive power demand in your system. When they detect a need, they adjust their output to supply the required reactive power. This simple yet powerful action boosts the power factor, reducing energy waste and improving the overall efficiency of your electrical infrastructure.

Success Stories: Active Filter Cabinets in Action

Let's take a look at a real - world example. A large manufacturing plant was facing persistent issues with its production line. Motors were burning out frequently, and the plant's energy bills were through the roof. After a thorough inspection, it was discovered that harmonics from the numerous variable - speed drives in use were the root cause. The plant installed an active filter cabinet tailored to their specific needs. Almost immediately, they noticed a difference. The motors stopped overheating, and the energy consumption dropped significantly. The plant's productivity increased as there were fewer unplanned shutdowns for equipment repairs. This is just one example of how active filter cabinets can transform an electrical system.

Choosing the Right Active Filter Cabinet for Your Needs

When it comes to selecting an active filter cabinet, there are a few things to keep in mind. First, you need to assess the size and complexity of your electrical system. The more extensive your system and the higher the harmonic distortion, the more powerful and sophisticated the active filter cabinet you'll need. Consider the type of electrical loads in your facility. Different loads generate different levels and types of harmonics, so you'll want a cabinet that can handle the specific challenges of your setup. Also, look for a cabinet that offers easy installation and maintenance. After all, you don't want to be spending hours trying to figure out how to install or service your new power - saving device.

In conclusion, active filter cabinets are not just another piece of electrical equipment. They're a game - changer for any industrial or commercial operation that values efficiency, reliability, and cost - savings. By effectively dealing with harmonics and reactive power issues, they can breathe new life into your electrical system. So, if you're tired of battling power quality problems, it might be time to consider adding an active filter cabinet to your electrical toolkit.

What is the difference between AHF and PHF?

AHFs can reduce multiple frequencies simultaneously. PHFs typically filter individual harmonics. AHFs can actively adjust to changes in the power grid's harmonic current within a certain range. PHFs can only reduce the harmonics of fixed orders (3,5,7) within a certain frequency range.

What is an AHF panel?

An Active Harmonic Filter (AHF) provides an effective means to mitigate harmonics, reduce process-related voltage fluctuations and improve equipment operating life and system capacity. It can be part of a power factor correction and harmonic filtering system.

How Do Active Harmonic Filters Work?

AHF continuously monitors the load current and injects compensating currents to counteract the harmonics. AHF creates a current waveform that is the exact opposite of the harmonic distortion. This process cancels out the harmonic currents.