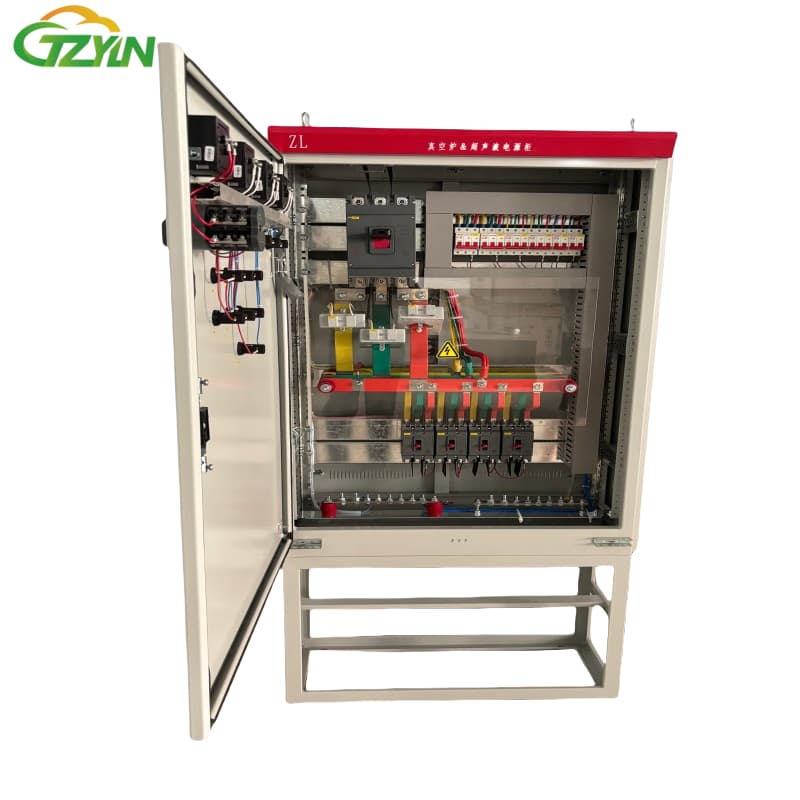

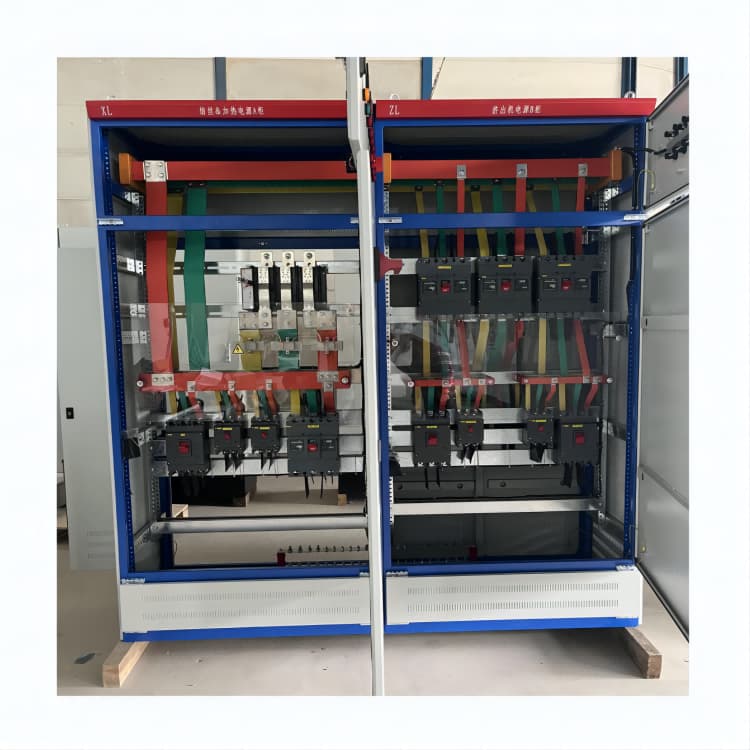

Power Distribution Panel Troubleshooting Tips

Aug 05, 2024

The distribution panel is an important part of the power system, responsible for distributing electrical energy from the power source to various loads. During long-term operation, the distribution panel may fail for various reasons, affecting normal power supply. Mastering some troubleshooting techniques is essential to ensure the stable operation of the power system.

1. Mechanical fault inspection: The power distribution panel contains two parts, mechanical and electrical. Failure of the mechanical part may cause problems in the electrical part. Therefore, you should first check whether the mechanical parts, such as switches and contactors, have failed due to mechanical damage.

2. Electrical fault inspection: After confirming that there is no problem with the mechanical part, check the electrical part, including whether there is a circuit break, short circuit or poor contact in the line and terminal.

3. Visual inspection: Use the simplest and easiest method to check at the beginning, such as observing whether there are obvious fault phenomena such as fuse breaking, switch tripping, etc.

4. Complex method: If the simple method cannot solve the problem, use more complex detection methods, such as using a multimeter to measure resistance and voltage.

5. External inspection: Without disassembling the equipment, check whether the switches and indicator lights on the equipment panel are working properly through external operation to minimize the scope of the fault.

6. Internal inspection: If the external inspection cannot solve the problem, open the distribution panel to check the status of the internal components and connecting wires.

7. Static inspection: Check the resistance, wiring, etc. in the power-off state to avoid expanding the scope of the fault or causing unnecessary losses after power is turned on.

8. Dynamic inspection: After completing the static inspection and confirming safety, turn on the power to measure dynamic parameters such as voltage and current.

9. Public circuit inspection: Prioritize the public circuits of the distribution panel, such as the power input line, as failures in these circuits can affect the operation of the entire system.

10.Dedicated circuit inspection: After confirmng that there is no problem with the public circuit, check the dedicated circuits connected to the specific loads.

11.Dealing with common faults: First deal with common faults in the power distribution panel, such as poor contact, blown fuses, etc. These problems are generally easy to solve.

12.Solving complex faults: After eliminating common faults, focus on solving those rare and complex electrical faults.

Distribution panel troubleshooting requires a systematic strategy and rich practical experience. By mastering the above troubleshooting techniques, you can efficiently and accurately find and solve problems. At the same time, regular maintenance and inspection are key measures to prevent failures, help extend the service life of the distribution panel and ensure the stable operation of the power system.