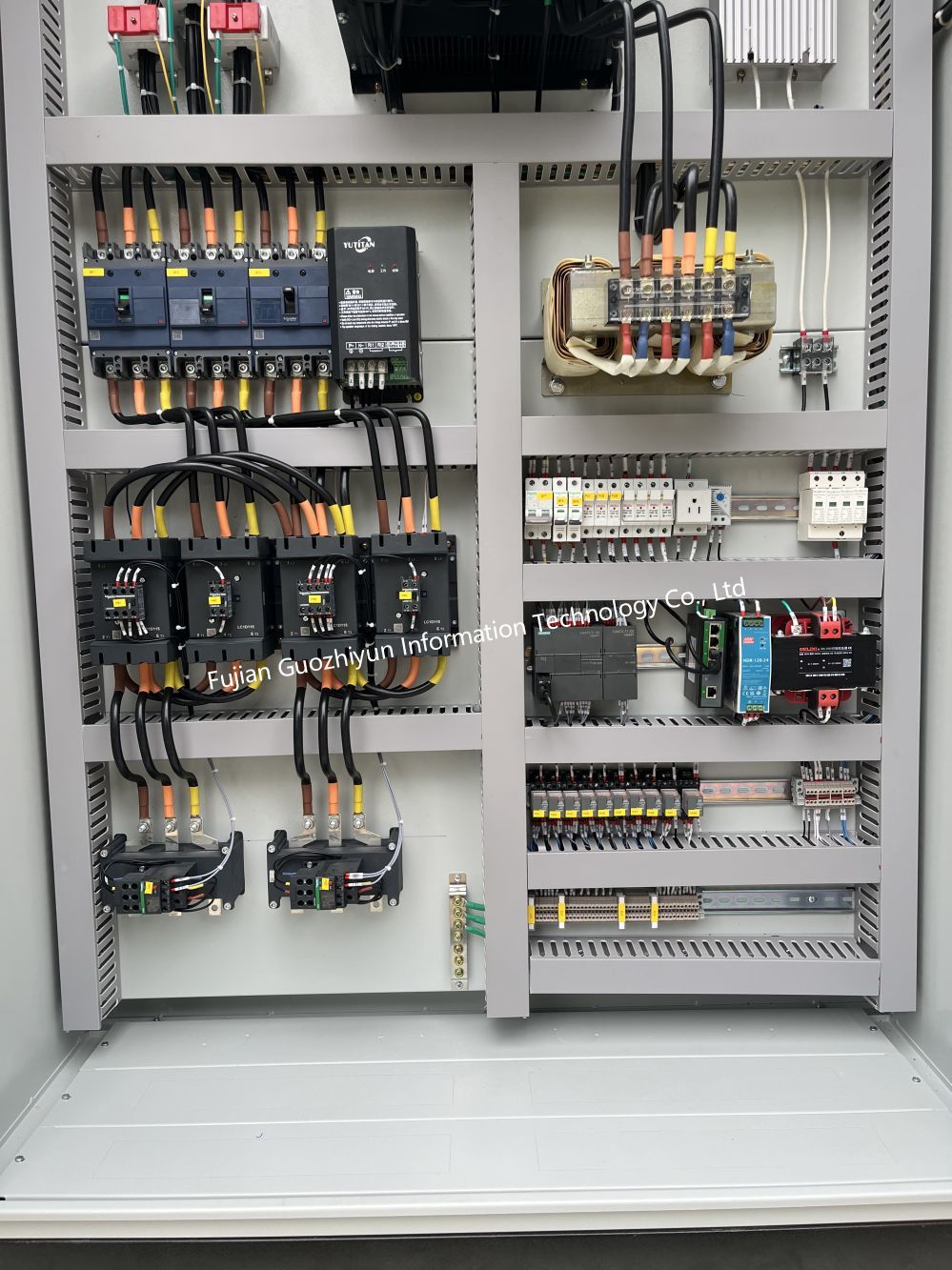

Related knowledge of frequency conversion control cabinet

May 23, 2024The main function of the frequency conversion control cabinet is to adjust the operating frequency of the equipment so that the equipment can work smoothly, thereby reducing energy consumption. The control cabinet generally has communication functions, macro functions, analog input control functions, etc. It has distinctive features. It not only has low operating costs, but also saves energy. It can improve the pressure control accuracy, extend the service life of the motor and reduce noise.

Working principle of frequency conversion control cabinet

The core device of the frequency conversion control cabinet is the frequency converter. The speed of the motor mainly depends on the power supply frequency. In addition to a small slip rate, the asynchronous motor's speed is basically proportional to the power supply frequency. The speed of the synchronous motor is strictly proportional to the power supply frequency. Proportional. By adjusting the output frequency of the inverter, the motor speed can be changed. The frequency conversion control cabinet is mainly used to adjust the operating frequency of the equipment, reduce energy loss, start the equipment smoothly, and reduce the damage to the motor caused by the large current generated when the equipment is started directly. It also comes with analog input (for speed control or feedback signal), PID control, pump switching control (for constant pressure), communication function, macro function (different parameter settings for different occasions), multi-speed, etc. . It can be widely used in automatic control of water supply, drainage, fire protection, sprinkler pipe network pressurization, HVAC hot and cold water circulation and other occasions in industrial and agricultural production and various buildings.

Frequency conversion control cabinet design specifications

1. General: Before designing and installing the frequency conversion control cabinet, the designer must not only consider the normal working conditions of the frequency conversion control cabinet, but also consider possible fault conditions, foreseeable misoperations, and excessive changes in temperature, pollution, humidity, and grid power supply. External influences such as voltage and harmonic interference. The structure should be beautiful and the size should be reduced as much as possible to facilitate transportation.

2. Cabinet requirements:

Isolation of the control cabinet: It is convenient to install noise filters, DC filters, and output reactors at the front and rear ends.