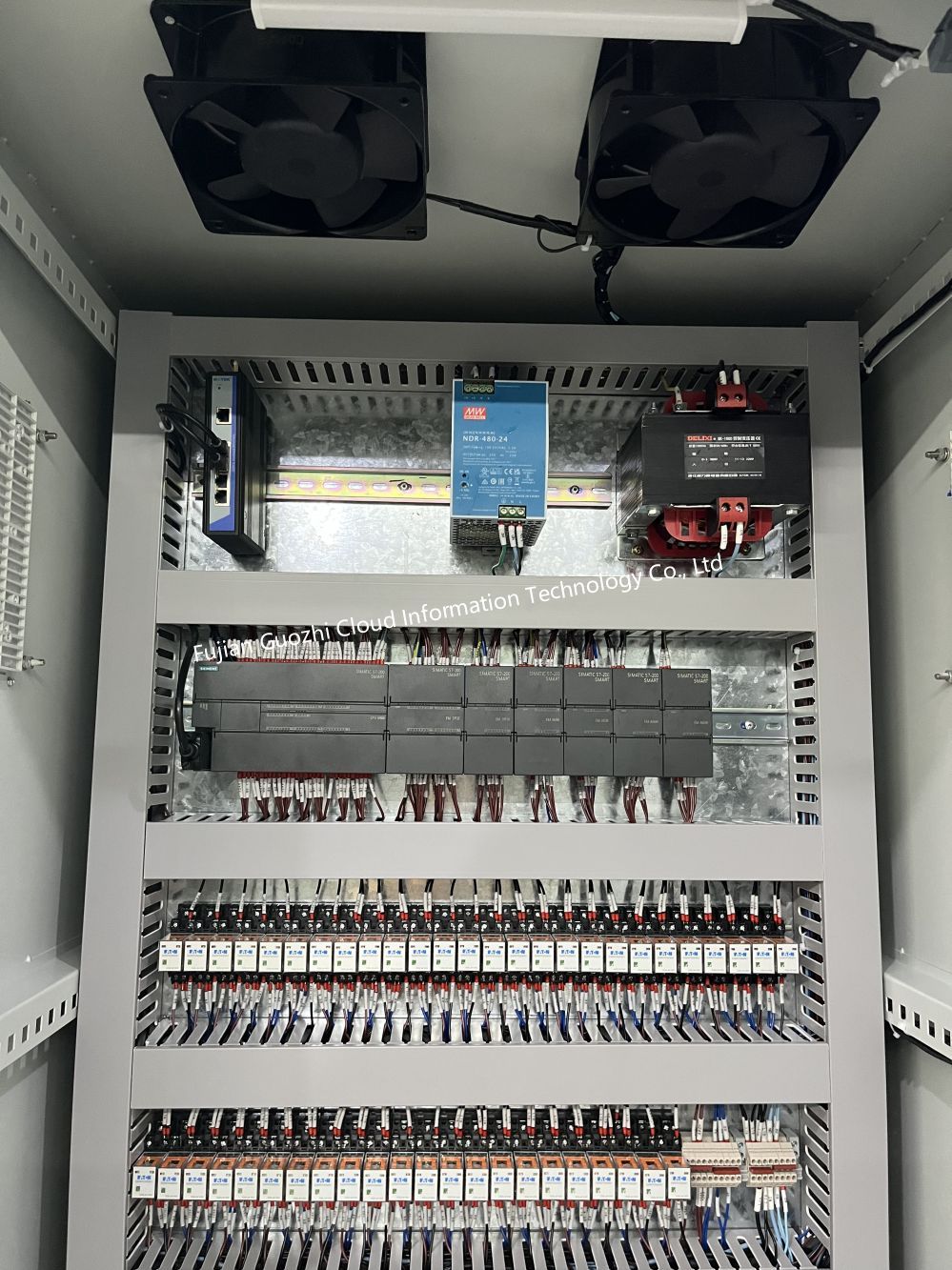

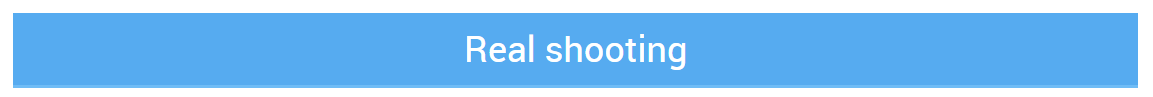

Crane control box is a device used to control the operation of a crane

Item No :

GZY-ADLYOrder(MOQ) :

3 unitsPayment :

T/T、PaypalProduct Origin :

Fujian/FuzhouColor :

Carbon steel/stainless steelShipping Port :

Ningbo,Mawei,ShenzhenLead Time :

30 daysWeight :

customizedIt usually includes the following parts:

1. Main controller: The main controller is the core part of the crane control box, responsible for receiving and processing instructions from operators, as well as monitoring the operation status of the crane.

2. Operation panel: The operation panel is the interface where the crane operator interacts with the main controller, usually including various buttons, switches, and display screens.

3. Sensors and actuators: Sensors are used to detect various operating parameters of cranes, such as hook height, load weight, crane speed, etc. The actuator is used to control the crane according to the instructions of the main controller, such as starting/stopping the motor, controlling the brake, etc.

4. Communication module: The communication module is used to achieve data exchange between the crane control box and other devices (such as remote controllers, monitoring centers, etc.).

5. Power module: The power module provides stable power to the crane control box, usually including components such as transformers, rectifiers, filters, etc.

6. Protection device: The protection device is used to ensure the safe operation of the crane in abnormal situations, such as overload protection, short circuit protection, overheating protection, etc.

We are used to working with the most reknowned brands and we are able to recommend the ones that best fit your application and your budget. let us assist you in designing the most cost efficient control panel for your application.

The main functions of the crane control box include:

1. Implement automatic and manual control of the crane to improve operational efficiency and safety.

2. Real time monitoring of the operation status of the crane, such as hook height, load weight, crane speed, etc., to ensure that the crane operates within a safe range.

3. Implement fault diagnosis and alarm functions for cranes, timely detect and handle faults, and avoid accidents.

4. Exchange data with other devices through communication modules to achieve remote monitoring and control.

Constant pressure water supply, air compressor, fan and water pump, central air conditioning, port machinery, machine tools, boilers, papermaking machinery, food machinery

Tags :

Control system PLC programmable DCS system variable frequency control board

Factory Hot Sale Electrical Equipment Electrical Distribution Panel

Active harmonic filter is connected in parallel with non-linear loads, and uses one set of CT to detect the load current. The AHF system can also improve power factor (PF) and correct load imbalances in the power system.

The school power distribution cabinet operates by receiving electricity from the grid, distributing it via internal switchgear and control systems to various areas based on demand, and employing protection devices like circuit breakers and fuses to monitor and safeguard against electrical faults such as short circuits, overloads, or leakages, thereby ensuring equipment and personnel safety.

It is a centralized control and distribution device designed specifically for electric motors, integrating functions such as power distribution, equipment control, fault protection, and intelligent monitoring,

Distribution cabinet The distribution cabinet is a complete set of switchgear and control equipment, mainly used for the control, monitoring, measurement, and protection of power lines and major electrical equipment.

The generator synchronization panel is a control device used for parallel operation of generator sets. It uses precise control algorithms and hardware equipment to achieve synchronization of voltage, frequency and phase between multiple generator sets to ensure stable power supply of the power system.

Automatic transfer switchgear is used for automatic transfer between the main power supply (mains) and the backup power supply (generator set or other power sources), with reliable operation, simple use, compact structure, and high cost-effectiveness.

The ultrasonic power supply cabinet converts the mains electricity into high-frequency alternating current, and then transmits the electrical energy to the transducer through a series of circuit processing and control, so that it generates high-frequency vibration. The power supply cabinet can also adjust the output voltage, current, frequency and other parameters according to different working requirements to ensure the stable operation and optimal performance of the transducer.

The power supply AB cabinet is an efficient and stable power distribution equipment, designed to automatically switch between the main power supply and the backup power supply to ensure continuous power supply to the load. It is suitable for various industrial, commercial and residential environments, and has multiple protection functions such as overload protection, short circuit protection, etc. to ensure the safe operation of the power system.

The working principle of the outdoor distribution box is to realize the control, protection and monitoring functions of the circuit through the internal electrical wiring and component configuration. In normal operation, it can manually or automatically connect or disconnect the circuit; in the event of a fault or abnormality, it can automatically cut off the circuit or send out an alarm signal; at the same time, it can also display operating parameters through measuring instruments and allow users to make necessary adjustments.

Electrical Metal Panel Box, Low Voltage Distribution 690V Drawer Cabinet Switchgear Panel

The crane control cabinet is an indispensable part of the crane system. It is responsible for receiving operating instructions and converting them into mechanical actions to achieve precise control of the crane's lifting, running, steering and other mechanisms. The control cabinet usually contains various electrical components, such as contactors, relays, inverters, etc., as well as devices for protecting these components, such as circuit breakers and fuses.

Power cabinets are generally made of metal materials and have certain protective properties, such as rain, dust, corrosion, etc

Customized vertical electrical distribution box cabinet is an electrical equipment designed and manufactured according to specific needs, used for centralized installation and control of electrical components and lines.

Distribution cabinet The distribution cabinet is a complete set of switchgear and control equipment, mainly used for the control, monitoring, measurement, and protection of power lines and major electrical equipment.

The water pump control cabinet has multiple protection functions and complete status display, including overload, short circuit, phase loss protection, pump body leakage, motor overheating and leakage protection. It also has single pump and multi pump control working modes, multiple main and backup pump switching modes, and various starting modes.

Automatic transfer switchgear is used for automatic transfer between the main power supply (mains) and the backup power supply (generator set or other power sources), with reliable operation, simple use, compact structure, and high cost-effectiveness.

Motor control cabinet is an electrical equipment specifically designed to control the operation of motors.

Scope of application: The street light control box is used to control street lights, tunnel lights, community lights, landscape lights, square lights, and other related street lights.

A distribution box is a low-voltage distribution box composed of switchgear, measuring instruments, protective appliances, and auxiliary equipment assembled in a closed or semi closed metal cabinet or screen according to electrical wiring requirements.

ATS control cabinet, also known as automatic transfer switching equipment control cabinet, is mainly used in emergency power supply systems.

The distribution cabinet (box) is divided into power distribution cabinet (box), lighting distribution cabinet (box), and metering cabinet (box), and is the final equipment of the distribution system.

The distribution box, distribution cabinet, distribution panel, distribution panel, electrical cabinet, etc. are a complete set of devices for centralized installation of switches, instruments, and other equipment.

The distribution box, distribution cabinet, distribution panel, distribution panel, electrical cabinet, etc. are a complete set of devices for centralized installation of switches, instruments, and other equipment.

Definition They refer to the final equipment of the power distribution cabinet, lighting distribution cabinet, metering cabinet, and other distribution systems.

Distribution cabinets, also known as electrical cabinets, are key equipment in the power system, mainly serving as distribution and control centers for power loads.

They refer to the final equipment of the power distribution cabinet, lighting distribution cabinet, metering cabinet, and other distribution systems.

A distribution panel, also known as a distribution cabinet, is a device that concentrates, switches, and distributes electrical energy.

Crane control box is a device used to control the operation of a crane

A dual power distribution cabinet, also known as a dual power control cabinet, is a device composed of a dual power automatic switching device.

Power cabinets are generally made of metal materials and have certain protective properties, such as rain, dust, corrosion, etc

The commonly used electrical components in the electrical control cabinet include circuit breakers, contactors, intermediate relays, thermal relays, buttons, indicator lights, universal transfer switches, and travel switches.

Distribution cabinets can be divided into power distribution cabinets (boxes), lighting distribution cabinets (boxes), and metering cabinets (boxes).

Hospital customized distribution box electrical control panel low voltage electrical switch cabinet.

Suitable for various occasions such as shopping malls, hospitals, schools, factories, and office buildings, our distribution cabinets can provide stable and reliable power support for lighting, power, and backup power. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Distribution cabinets can be divided into power distribution cabinets (boxes), lighting distribution cabinets (boxes), and metering cabinets (boxes). Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Electric meter box: The electric meter cabinet is a specialized cabinet used for installing energy metering devices. Its main function is to record and display the electricity consumption Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Distribution board: Distribution board is a kind of equipment used to centralize, switch and distribute electric energy, which is usually composed of cabinet, switch (circuit breaker), protection device, monitoring device, electric energy meter and other anime devices. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Power control box A power control box is a device used for centralized management and control of power supply, typically used in various industrial, commercial, and residential applications. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

distribution box According to different usage scenarios and functions, distribution boxes can be divided into primary, secondary, and tertiary distribution boxes. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Distribution panel The distribution panel is an indispensable component of the power system, which not only ensures the effective distribution of electrical energy, but also provides necessary protective measures to ensure the safe and reliable operation of the power system. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Distribution panel The distribution panel is an indispensable component of the power system, which not only ensures the effective distribution of electrical energy, but also provides necessary protective measures to ensure the safe and reliable operation of the power system. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Distribution cabinet The distribution cabinet is a complete set of switchgear and control equipment, mainly used for the control, monitoring, measurement, and protection of power lines and major electrical equipment. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

electrical control cabinet Electrical control cabinet, also known as electrical control cabinet, is a type of equipment that assembles switchgear, measuring instruments, protective appliances, and auxiliary equipment into enclosed or semi enclosed metal cabinets or screens according to electrical wiring requirements. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

Petrochemical electrical distribution panels are usually combined with DCS (distributed control system) to achieve precise control and regulation of the production process, ensuring production stability and efficiency. Soft start control cabinet is an electrical equipment used for motor control, which can reduce the starting current, reduce the impact on the distribution system, and extend the service life of the motor and related equipmen

The factory distribution cabinet is a key equipment used in the power system for distributing, controlling, and protecting electrical energy.

I/O cabinets usually have system power and access power inside, which are used to provide stable power supply for various electronic components.

PLC panels and control systems combine various functions into a compact, customizable, and easily integratabtle system.

Power Distribution Cabinet 380V Motor Control Center.

Low voltage control panel box electrical 230v/400v electrical control panel board distribution cabinets.

High Quality Low Voltage Control Panel MCCB Electrical Enclosures Power Panel Distribution Board.

Outdoor Low Voltage Integrated Box Outdoor Power Distribution Cabinet

Electrical equipment supplies low voltage power switchgear power distribution cabinet series

Custom oem china Power distribution cabinet lighting power distribution box low voltage power distribution cabinet

Refrigeration equipment power distribution control integrated cabinet is a device that integrates refrigeration system control and power distribution. It is usually used in building air-conditioning systems, cold storage and other occasions that require precise temperature control.

Power Panel 800A 1200A 3000A Transformer 415V LV PDU Power Distribution Cabinet Electrical Switchgear

Low-Voltage Power Distribution Reactive Power Compensation Integrated Cabinet Capacitor Bank

low voltage distribution cabinet is suitable for three-phase AC 50/60HZ, max voltage 690V, rated current to 800A power distribution system,Used to control motor starting, power and lighting, indoor wall installation, front panel operation, front panel inspection; Cabinet is fully enclosed structure, by welding profile assembly.

Low Voltage Lighting Distribution Box power distribution equipment control panel for lighting.

Auto Automatic Transfer Switching Equipment ATS Panel Power Distribution Switchgear 11KV 12KV.

Low Voltage Electrical Main Power Distribution Board Metal Electric Unit Cabinet

/ats-dual-power-automatic-conversion-electrical-control-panel-cabinetATS (Automatic Transfer Switch) Panel Power Distribution, an automatic transfer switch panel power distribution system, is an electrical device that can automatically switch to a backup power source in the event of a power failure or interruption.

The distribution box, distribution cabinet, distribution panel, distribution panel, electrical cabinet, etc. are a complete set of devices for centralized installation of switches, instruments, and other equipment.

The commonly used electrical components in the electrical control cabinet include circuit breakers, contactors, intermediate relays, thermal relays, buttons, indicator lights, universal transfer switches, and travel switches.

ATS control cabinet, also known as automatic transfer switching equipment control cabinet, is mainly used in emergency power supply systems.

Electrical control cabinet, also known as electrical control cabinet, is a type of equipment that assembles switchgear, measuring instruments, protective appliances, and auxiliary equipment into enclosed or semi enclosed metal cabinets or screens according to electrical wiring requirements.

A distribution box is a low-voltage distribution box composed of switchgear, measuring instruments, protective appliances, and auxiliary equipment assembled in a closed or semi closed metal cabinet or screen according to electrical wiring requirements.

The distribution box, distribution cabinet, distribution panel, distribution panel, electrical cabinet, etc. are a complete set of devices for centralized installation of switches, instruments, and other equipment.

Distribution cabinets, also known as electrical cabinets, are key equipment in the power system, mainly serving as distribution and control centers for power loads.

low voltage distribution cabinet is suitable for three-phase AC 50/60HZ, max voltage 690V, rated current to 800A power distribution system,Used to control motor starting, power and lighting, indoor wall installation, front panel operation, front panel inspection; Cabinet is fully enclosed structure, by welding profile assembly.

Low Voltage Lighting Distribution Box power distribution equipment control panel for lighting.

Low voltage control panel box electrical 230v/400v electrical control panel board distribution cabinets.

Motor control cabinet is an electrical equipment specifically designed to control the operation of motors.

F17A 2x75kw electric motor soft start distribution control cabinet.The motor soft start control cabinet is a type of motor control device that can achieve smooth and impactless starting of the motor throughout the entire starting process. It can also adjust the parameters during the starting process, such as current limit value and starting time, according to the characteristics of the motor load.

Crane control box is a device used to control the operation of a crane

The street light control box is used to control street lights, tunnel lights, community lights, landscape lights, square lights, and other related street lights.

The water pump control cabinet has multiple protection functions and complete status display, including overload, short circuit, phase loss protection, pump body leakage, motor overheating and leakage protection. It also has single pump and multi pump control working modes, multiple main and backup pump switching modes, and various starting modes.

Suitable for various occasions such as shopping malls, hospitals, schools, factories, and office buildings, our distribution cabinets can provide stable and reliable power support for lighting, power, and backup power.

A dual power distribution cabinet, also known as a dual power control cabinet, is a device composed of a dual power automatic switching device.

Electrical equipment supplies low voltage power switchgear power distribution cabinet series

Refrigeration equipment power distribution control integrated cabinet is a device that integrates refrigeration system control and power distribution. It is usually used in building air-conditioning systems, cold storage and other occasions that require precise temperature control.

Custom oem china Power distribution cabinet lighting power distribution box low voltage power distribution cabinet

They refer to the final equipment of the power distribution cabinet, lighting distribution cabinet, metering cabinet, and other distribution systems.

They refer to the final equipment of the power distribution cabinet, lighting distribution cabinet, metering cabinet, and other distribution systems.

Power Panel 800A 1200A 3000A Transformer 415V LV PDU Power Distribution Cabinet Electrical Switchgear.

Electrical Metal Panel Box, Low Voltage Distribution 690V Drawer Cabinet Switchgear Panel

Electric meter box: The electric meter cabinet is a specialized cabinet used for installing energy metering devices. Its main function is to record and display the electricity consumption

Automation high Low Voltage Electrical control Cabinet / Distribution Box / Switchgear.

The shopping mall distribution cabinet is the core component of the shopping mall's power system, and is mainly responsible for the distribution, control and protection of electrical energy.

The distribution box, distribution cabinet, distribution panel, distribution panel, electrical cabinet, etc. are a complete set of devices for centralized installation of switches, instruments, and other equipment.

The power distribution control panel is a key component in the power system. It is not only responsible for efficiently distributing electricity to where it is needed, but also ensuring the safe and stable operation of the power system.

The switchboard is an essential part of the electrical system and is the central hub for safe and efficient power distribution. It houses a range of electrical components, including switches, circuit breakers and transformers, and is responsible for regulating and directing the flow of electricity throughout a building or industrial facility.

Power distribution control switchgear is a set of switchgear and control equipment, which is mainly used for opening and closing, controlling and protecting electrical equipment in the process of power generation, transmission, distribution and energy conversion in power systems.

The distribution cabinet should be made of non-combustible materials, and the structure should be open, closed, sealed or explosion-proof according to the risk of electric shock in the place.

As an important part of the power system, the distribution cabinet not only carries the basic functions of distributing and controlling electric energy, but also improves the operating efficiency and safety of the power system through continuous technological innovation and intelligent development.

The distribution cabinet plays a vital role in the power system, ensuring the stability and safety of the power system through reasonable power distribution, comprehensive circuit protection, real-time operation monitoring and precise control operation.

Customized distribution cabinets can better adapt to non-standard installation sites and special application requirements, such as specific size restrictions, integration of special functions, etc.

The distribution cabinet is an important device used to distribute and control electric energy in the power system. It assembles switchgear, measuring instruments, protective electrical appliances and auxiliary equipment in a closed or semi-closed metal cabinet according to the electrical wiring requirements.

A switchboard is an electrical device used to distribute and control electrical energy in a circuit and is usually installed in the electrical systems of various facilities.

Switchboards are widely used in industrial facilities, commercial buildings and residences, and are particularly crucial in shipboard power systems.

A distribution board is a device that concentrates, switches and distributes electrical energy, usually consisting of a cabinet, switches, protection devices, monitoring devices, electric energy meters and other secondary components.

Metal control enclosure industrial electrical cabinet power distribution cabinet Customized Automation Control Box.

An electrical control cabinet is a centrally installed cabinet that is equipped with switchgear, measuring instruments, protective electrical appliances and auxiliary equipment for the control and protection of power systems.

The power distribution cabinet plays a vital role in the power system. It is mainly used to distribute electrical energy and protect, monitor and control the circuit.

A distribution board is an electrical device used to distribute electrical power to numerous individual circuits or consumption points in a single or three phase supply.

The pump control cabinet is an electrical device mainly used to automatically control the operation and protection of various types of water pumps.

The generator ATS cabinet is a control cabinet for automatic transfer switchgear, which is used to realize automatic switching between diesel generator sets and mains power, ensuring that critical loads can continue to operate stably when power is interrupted.

The frequency conversion control cabinet is an indispensable part of the modern automation system. Through efficient motor control technology, it not only improves the operating efficiency of the system, but also greatly saves energy consumption.

Rittal electrical control cabinet is a high-quality, high-performance electrical control cabinet, which is widely used in industrial automation and power control systems.

Rittal cabinets are high-quality, high-performance cabinets that are primarily used in the fields of information technology and telecommunications to store and protect a variety of network equipment and servers.

Rittal cabinets are widely used in industrial control, data centers, power facilities and other fields, and can meet the specific needs of different industries.

A control cabinet is a cabinet used to centrally install various electrical control systems, and is commonly used in industrial automation and power system control.

Electrical control boxes are mainly used in power systems and industrial automation to control, protect and monitor equipment. Their functions include power on/off control, voltage regulation, current control, motor direction control.

An electrical control box is a specialized device used to integrate and protect components in an electrical control system.

Control cabinets are commonly used in power systems, industrial production and building automation to control and protect various electrical equipment.

The soft start control cabinet is an electrical device used for motor starting control. It extends the service life of the motor and related equipment by reducing the starting current of the motor and reducing the starting stress.

An electrical control cabinet is a closed or semi-closed metal cabinet that centrally installs switchgear, measuring instruments, protective electrical appliances and auxiliary equipment.

Capacitor compensation cabinets improve the power factor in the power system by connecting capacitors in parallel, thereby reducing energy waste and improving equipment utilization.

Lighting distribution cabinets are divided into two types according to the installation method: closed hanging type (exposure installation) and embedded type (concealed installation). The box material can be divided into steel box, switchgear stainless steel box, iron box and plastic box.

The frequency conversion control cabinet is an electrical control device used to adjust the operating frequency of the equipment to reduce energy loss and start the equipment smoothly.

The power distribution panel undertakes the important tasks of distributing, controlling and protecting electric energy to ensure the safe and stable operation of the power system.

The power distribution cabinet is a key equipment in the power system, which is used to centrally distribute and manage electric energy to ensure the normal operation of various electrical equipment.

ATS control cabinet is a control system for automatic transfer switch electrical appliances, mainly used in emergency power supply systems to ensure that it can automatically switch to the backup power supply when the main power supply fails, so as to ensure the continuity and reliability of power supply.

The power supply cabinet for drafting auxiliary machine is a power supply device specially designed for drafting auxiliary machine. It converts the input AC power into a high-frequency AC signal that matches the drafting auxiliary machine to drive the ultrasonic transducer to work. The power supply cabinet has safety functions such as overload protection and short circuit protection to ensure that the equipment can operate safely and stably in various working environments.

Tel : +86-18960903717

Email : [email protected]

WhatsApp : +8618960903717

Juze Center Factory, No. 105, High-tech Avenue, Shangjie Town, Minhou County, Fuzhou City

© 2025 Fujian Guozhiyun Information Technology Co., Ltd All Right Reserved.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)