What is the Difference Between Switchgear and Distribution Cabinets?

May 23, 2024

The Differences Between Switchgear and Distribution Cabinets are as Follows:

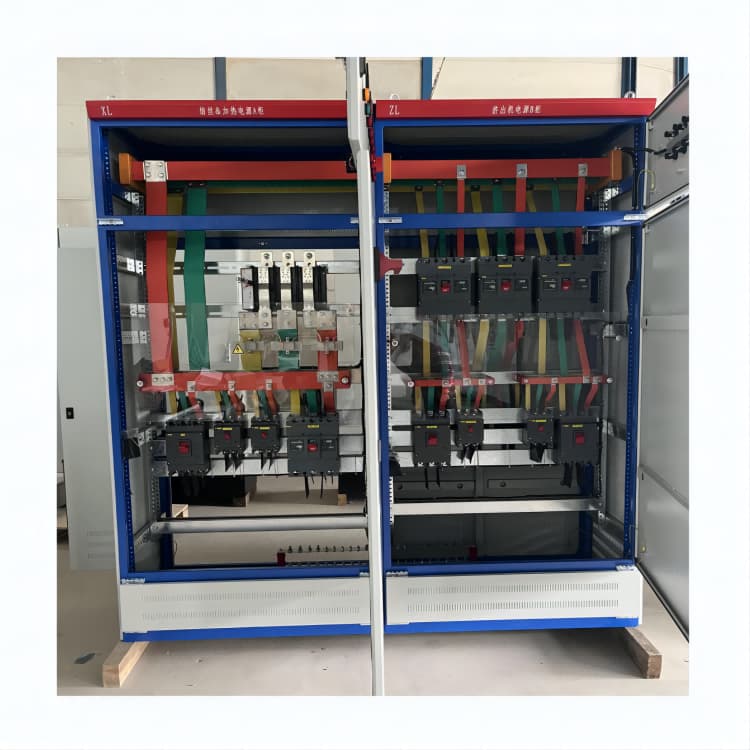

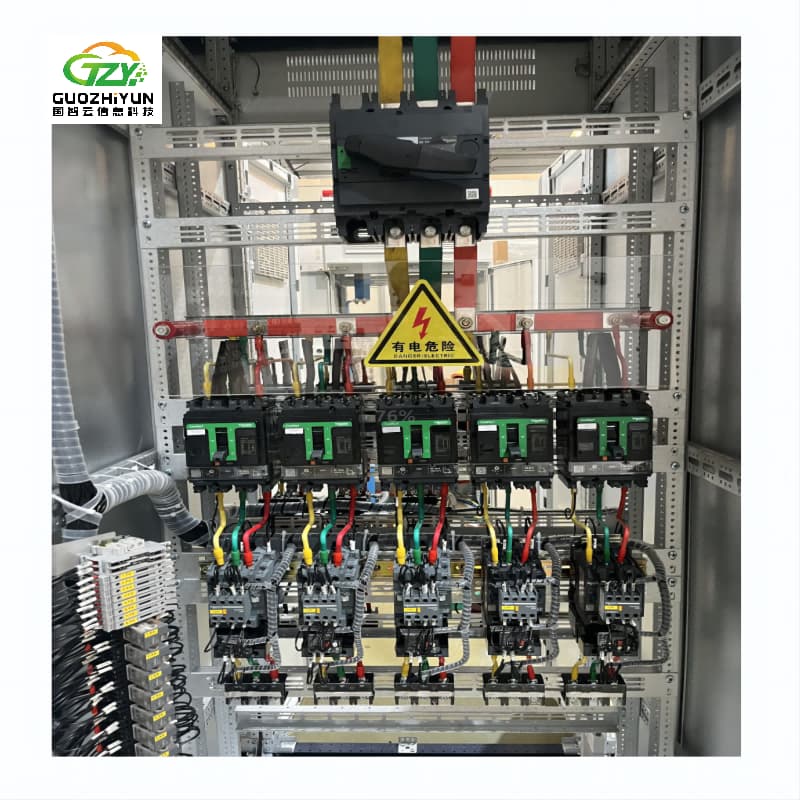

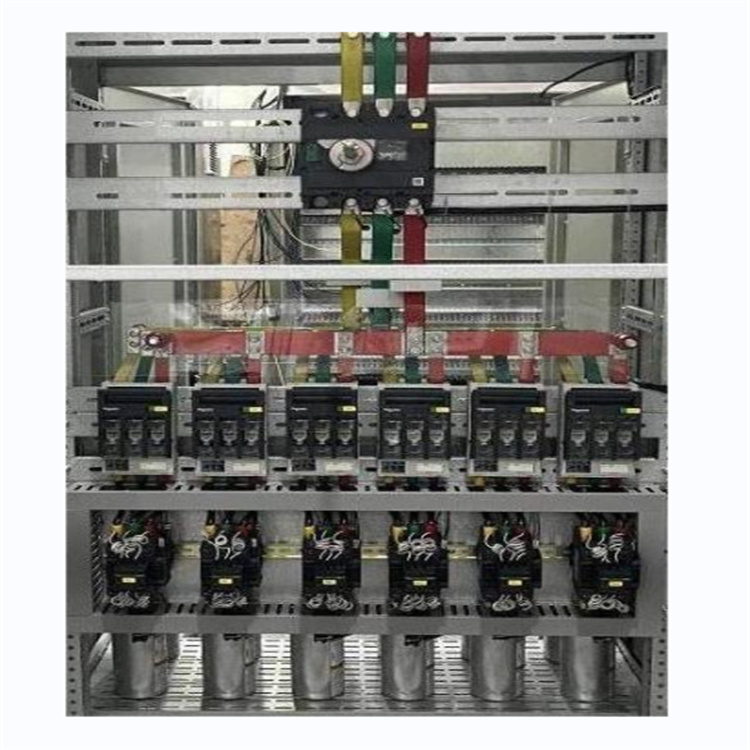

1. The function is different: switchgear is a complete set of electrical switchgear and control equipment, it is used as a power center and the main distribution device, mainly to play the role of a switch on and off. And distribution cabinet is to plays the function of distribution of electrical energy, line overload, short circuit, leakage protection role.

2. Different sizes: switchgear cabinet volume, general height in 1800mm, 2000mm, and 2200mm three, etc. And distribution cabinet volume is small, generally common only palm-sized, can be concealed in the wall, can also stand on the ground.

3. There are differences in installation sites: switchgear cabinets are often set up in substations, distribution rooms, and other places. Distribution cabinets can be installed in a variety of places, such as schools, institutions, hospitals, factories, workshops, families, etc.

4. The line material is different: switchgear cabinet mainline is often dominated by copper row, while the distribution box inside more wires.

5. Different components: low-voltage cabinets with plastic case circuit breakers and frame circuit breakers mostly. And capacitor cabinets. And distribution boxes in the content of some more complex, common is a larger switch with a string of micro-breakers below.

Switchgear Selection Points are As Follows:

1. Choose a well-known brand because the switchgear is a complete set of combined products, once encountered technical problems, equipment maintenance. And replacement are relatively troublesome. So in the case of ample budget, you should try to choose a well-known brand, well-known brands encounter problems when the solution is more efficient.

2. Before buying and selling to the manufacturer to obtain the switchgear inspection qualification. If there is no is an irregular product. Secondly, we should see whether the components of the switchgear are configured according to the requirements of the drawings.

3. To consider the cabinet material, generally speaking, good quality switchgear, components such as brackets are imported aluminum zinc plate

4. In and out of the line way, the general switchgear has two kinds of connection: one is in and out of the line cable room connection. Another is the first in and out of the line from the top of the cabinet through the wall casing led. And bus bar bridge connected bus bar bridge and then through the good casing and overhead line connection. If the second is applied, to be installed at the time of the site to supervise the work.